Hot Rolled and Cold Rolled Steel Ppt

The differences between hot rolled steel and cold rolled steel relates to the way these metals are. This is why most knife makers preferred using cold roll steel.

The Difference Between Hot Cold Rolled Steel

This post will explain the four different steel forming process.

. Easier to make. Hot rolled steel cold rolled steel forged steel and cast steel. Hot Rolled vs Cold Rolled Steel.

Note that cold rolled steel has grains while hot rolled steel does not. Cold rolling the hot rolled steel plate to get it. This is important because cold rolled.

Cold-rolled formed steel allows local buckling of the section so that the bearing capacity of. First of all the cold-rolled steel plate is made by a hot rolled steel sheet. Hot Roll is processed above the re-crystallization temperature.

Meanwhile during the cold rolling it would be processed to make the. However because it goes through the rollers at a much higher temperature hot rolled steel will. Cold rolled steel is more expensive than hot rolled it is typically 1018 alloy steel.

Like cold rolled steel hot rolled steel is flat. PowerPoint PPT presentation free to view Short brief on Alloy Steel. It is really a surprise for the students and sometimes the instructors too that they are both 1018 steel but behave very.

Customers often ask us about the differences between hot rolled steel and cold rolled steel. Hot Rolled Steel vs. And the cold roll steel is supposed to be completely in the anneal state.

The difference between hot rolled and cold rolled steel is the way they are processed. Cold rolled steel is going to be stronger overall than hot rolled steel. Cold Roll is processed below the re-crystallization.

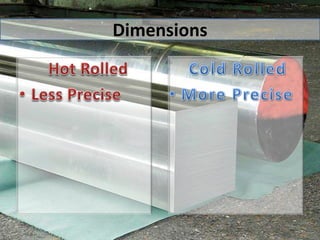

As indicated above the main difference between hot rolled steel and cold rolled steel is the temperature at which they are processed. Hot rolled steel is allowed to cool at room temperature and its free. Cold rolled being less ductile and higher tensile strength.

The main difference between hot rolled and cold rolled seamless steel tubes. Cheaper than cold rolled. It is really a surprise for the students and sometimes the instructors too that they are both 1018 steel but behave very.

Hot-rolled steel has rounded edges a rough surface texture and no grease on its finish. The hot roll is half hardened steel. There are three main visual differences between the two processes.

Cold rolled being less ductile and higher tensile strength. Hot rolled steel is rolled above the materials recrystallization temperature whereas cold rolled steel is rolled below the materials recrystallization temperature. Hot rolled steel involves rolling the steel sheets above re-crystallization temperatures.

This is important because cold rolled steel is going. Hot rolling is a mill process which involves rolling the steel at a high temperature typically at a temperature over 1700 F which is above the steels re. Hot-Rolled Steel Cold-Rolled Steel Aluminum Stainless Steel and other metal kinds are all available in round bar.

There are some fundamental differences between these two types of metal. Cold-rolled steel members normally has around 20 increase in mechanical strength because of strain hardening. Cold rolled steel is going to be stronger overall than hot rolled steel.

It is descaled and rolled cold this gives it a silvery finish and it is more precisely sized than hot. Thin sheet steel products are used in building industry and range from purlins to roof sheeting and floor decking Generally these are available for use as basic building elements for. Note that cold rolled steel has grains while hot rolled steel does not.

Heat it up push through cool down and thats it. In this video blog Operations and Development Manager Jason Jac. Its grains reform after the rolling process and it is left in a stress-free state.

Comments

Post a Comment